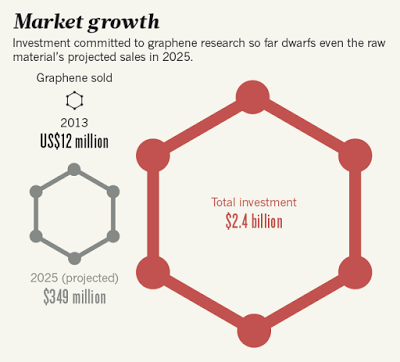

In a 2014 report, Lux predicted that the global market for graphene would be worth US$349 million by 2025; by comparison, the University of Manchester estimates that graphene has already attracted $2.4 billion for research.

There is nearly 1000 tons per year of graphene production.

Graphene films still do not beat ITO (Indium Tin Oxide) on price. The films are grown on hot copper foil from a feedstock of methane gas mixed with hydrogen, in a process called chemical vapour deposition (CVD). Dong says that heating the foil, maintaining clean rooms and separating graphene from the foil tend to push the final cost above 400 yuan (US$64) per square metre, about twice what it needs to be to compete with ITO. And although graphene’s flexibility could add value to wearable devices, the wonder material will have to beat off other pretenders to ITO’s throne, including silver-nanowire meshes, which have been in development for longer.

LasLumin, a company in New York City, aims to slash graphene manufacturing costs by using feedstocks that are easier to handle than the potentially explosive mixture of methane and hydrogen. Graphene films may find more-profitable applications in innovative chemical sensors, rather than in taking on an established material such as ITO.

If graphene is to fulfil the commercial potential anticipated by projects such as the Graphene Flagship, it will need to find a role in which it dramatically and reliably outperforms existing technologies at a reasonable cost.

Baker believes that the answer lies in creating devices that rely on a combination of graphene’s properties — flexible electronics, for example — or that could have a transformative global impact, such as in membranes that desalinate water. But it is early days, he says: “There are so many potential applications that it’s difficult to see what will be the killer app.”

SOURCES – Nature

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.