Canada’s Terrestrial Energy Corporation is a leader in molten salt reactors. Nextbigfuture believes they have a good chance at creating an energy revolution because of their low cost and low development risk design. Their main advantage is the Canadian oilsands. Hundreds of IMSR reactor can be used to generate steam for oil recovery.

Low cost and accessible energy supply is linked to living standards and quality of life. Higher standards of living make appliances and devices more affordable; emerging nations are craving all the gadgets and conveniences of the developed world. Per capita electricity consumption in the most developed nations, the countries of the Organization for Economic Cooperation and Development, the OECD, is 4½ times greater than in the rest of the world. In Canada, our per capita electricity consumption is over double the OECD average and 9½ times the non-OECD world. There are over 5.7 billion people who want to close that gap.

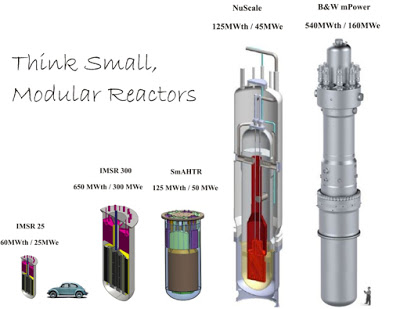

The 25 MWe version of the IMSR is the size of a fairly deep hottub

What is a molten salt reactor and how is it different?

Generically, it is a reactor system that uses a liquid fuel. This is a fundamental difference. All others use solid fuel. The fuel of a molten salt reactor consists of a molten salt mix that includes a fuel salt – in our case, uranium. This salt mix generates heat from the fission process under the right controlled conditions. Salt has a much higher boiling point than even highly pressurized water, so the MSR can generate outlet temperatures approaching 700 degrees Celsius compared to just over 300 degrees for a conventional nuclear plant. And it does that at atmospheric pressure. This avoids many of the engineering challenges and added costs associated with large pressure vessels or pressurized fuel channels, as in a Candu.

We know that the MSR works in a lab; this was demonstrated very clearly at Oak Ridge National Laboratory for a number of years. But it must work in the environment of private industry, where regulations, costs and commercial considerations drive decisions. It needs to be manufactured with materials from existing supply chains. It needs to be fueled with currently

available nuclear fuels. It needs to be built for market needs and not become a science project to showcase a concept. In short, it needs to pass the test of commercial viability – and we believe our IMSR does pass that test.It is here at the interface between the lab and market that we as a company have made our most important innovations.

One key innovation is the integration of primary reactor components (the moderator, primary heat exchanger and pumps) into a sealed reactor vessel within a compact and replaceable module, the IMSR Core-unit. The replaceable core-unit concept, unlike any other reactor design, leads to the properties that create high industrial value: passive safety, operational simplicity, and lower cost.

Our estimates indicate that the IMSR will demonstrate the lowest Lifetime Cost of Energy of any known technology, and by some margin.

With cost advantages come scale advantages as well, and that is important in our grid-challenged world. The IMSR meets the accepted definition of a small modular reactor. Its components, most importantly the IMSR Core-unit, are modular and transportable. They can be manufactured at a central production facility and can be transported to plant site on a flat-bed truck or by railcar. As a result, replacing Core-units can be done with minimal operational disruption; this preserves high utilization factors. IMSR technology is scalable, though, so our vision includes larger reactor designs that will be sized to meet the needs of both power generation and industrial process heat applications. Think oil sands. Think mining. Think desalination. Think petrochemicals, potash and ammonia production.

But we should not solve the market need solely through the prism of economics. As I mentioned earlier, nuclear needs a new narrative with Main Street for site licenses, for energy planning, and for public policy support. In this parallel arena, we have also innovated and have a new and fresh message, one based on passive safety and viable waste management.

As I mentioned earlier, the IMSR, and Molten Salt Reactors, in general, are entirely different reactor systems and, as such, have fundamentally different risk profiles. It is risk profiles that drive engineering requirements and costs. Molten Salt Reactors display excellent natural properties for decay-heat management and we have designed the IMSR to make the most of these properties. As such, the IMSR offers the possibility of passive safety rather than engineered safety – the IMSR design offers a “walk away safe” level of assurance: zero operator intervention, even with a total loss of site power.

The IMSR has a much smaller and relatively short-lived waste footprint. It burns its nuclear fuel far more completely and generates power with higher thermodynamic efficiency than solid fuel reactors. Together this leads to creation of only one-sixth of the long-lived Transuranic fuel waste (essentially, plutonium) per kilowatt hour compared to the nuclear plants we have today.

As those in the industry know very well, it is the long-term management of Transuranic fuel waste that is the most vexing waste management problem today – and we believe we address it convincingly. We can also make the statement that the IMSR will generate 30% less fission products per kilowatt hour, another challenging waste stream to manage but with a shorter time

horizon.

• lowest lifetime cost;

• high passive safety;

• scalability;

• use in industrial process heat markets, not just power;

• small plant footprints;

• grid and water independence, and;

• a dramatic reduction in the magnitude, toxicity and longevity of the waste stream.

Terrestrial Energy plans to build their first demonstration unit, an 80 megawatt thermal reactor, in Canada

Cost and Economics of the IMSR based upon comparison to existing reactor costs

Canadian David LeBlanc is developing the Integral Molten Salt Reactor, or IMSR. The goal is to commercialize the Terrestrial reactor by 2021.

Molten Salt and Oilsands

* Using nuclear produced steam for Oil Sands production long studied

* Vast majority of oil only accessible by In-Situ methods

* No turbine island needed so 30% to 40% the capital cost saved (instead of steam to turbine for electricity just send it underground to produce oil from oilsands)

* Oil sands producers expected to pay 200 Billion$ on carbon taxes over the next 35 years, funds mandated to be spent on cleantech initiatives

* Canada Oil Sands in ground reserves of 2 trillion barrels, current estimate 10% recoverable (likely much higher with cheaper steam)

* 64 GWth nuclear to add 6.4 million bbls/day (200B$/year revenue)

* 64 GWth needed as about 200 small 300MWth MSRs

* Oil Sands a bridge to MSRs then with time, MSRs a bridge to not needing oil

So each 300 MW thermal MSR would generate $1 billion per year in oil revenue from the oilsands.

A 300 MW thermal reactor would be the same as a 100 MW electrical reactor. Even if costs were as much proportionally as a $10 billion 1 GWe conventional nuclear reactor (the high costs of the most expensive european or US projects.) the $1 billion cost would be recovered in about 2-4 years. Also, they indicated that there is no turbine to produce electricity since only steam is used. So the costs should be $700 million max.

This profitability means that the first 200 units should easily be profitable. Usually making more units has a improvement rate in lowering costs by a few percentage points for each later unit. The oilsand units would also generate the money to help payoff research and development costs, which would initial come from oilsand taxes and oilsand partners.

IMSR design

* No fuel fabrication cost or salt processing = extremely low fuel costs

* Under 0.1 cents/kwh

* Right size reactors, right pressure steam

Looking at the cost components of current nuclear reactors

Old Nuclear Coal New LWR est IMSR first IMSR later 1 Fuel 5.0 11.0 5.0 0.1 0.1 2 Operating, Maintenance - Labor and Materials 6.0 5.0 8.0 1.0 0.2 3 Pensions, Insurance, Taxes 1.0 1.0 1.0 1.0 0.2 4 Regulatory Fees 1.0 0.1 1.0 1.0 1.0 5 Property Taxes 2.0 2.0 2.0 2.0 1.0 6 Capital 9.0 9.0 39.0 20.0 5.0 7 Decommissioning and DOE waste costs 5.0 0.0 5.0 0.5 0.1 8 Administrative / overheads 1.0 1.0 1.0 1.0 1.0 Total 30.0 29.1 60.0 27.6 8.6

Nextbigfuture thinks the IMSR can get down to 0.86 cents per Kwh.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.