The electric sail (ESAIL), invented by Dr. Pekka Janhunen at the Finnish Kumpula Space Centre in 2006, produces propulsion power for a spacecraft by utilizing the solar wind. The sail features electrically charged long and thin metal tethers that interact with the solar wind. Using ultrasonic welding, the Electronics Research Laboratory at the University of Helsinki successfully produced a 1 km long ESAIL tether. Four years ago, global experts in ultrasonic welding considered it impossible to weld together such thin wires. The produced tether proves that manufacturing full size ESAIL tethers is possible. The theoretically predicted electric sail force will be measured in space during 2013.

An electric solar wind sail, a.k.a electric sail, consists of long, thin (25?50 micron) electrically conductive tethers manufactured from aluminium wires. A full-scale sail can include up to 100 tethers, each 20 kilometres long. In addition, the craft will contain a high-voltage source and an electron gun that creates a positive charge in the tethers. The electric field of the charged tethers will extend approximately 100 metres into the surrounding solar wind plasma. Charged particles from the solar wind crash into this field, creating an interaction that transfers momentum from the

solar wind to the spacecraft. Compared with other methods, such as ion engines, the electric sail produces a large amount of propulsion considering its mass and power requirement. Since the sail consumes no propellant, it has in principle an unlimited operating time.

The electric sail is raising a lot of interest in space circles, but until now it has been unclear whether its most important parts, i.e. the long, thin metal tethers, can be produced.

The planned space missions and funded projects for the esail are:

ESAIL EU FP7 project

The ESAIL EU FP7 project (2011-2013) develops laboratory prototypes (TRL 4-5) of the key components of the E-sail. The project involves five countries, nine institutes and has a budget of about 1.7 million Euros.

* Deploy and confirm the deployment of a 10 m conductive Hoytether from a 1U CubeSat

* Test of a 100 m tether deployment on Aalto-1 3U CubeSat (2014)

Solar Wind Electric Sail Test (SWEST)

SWEST (Solar Wind Electric Sail Test) is a proposal to the EU whose purpose is to build a flight-ready 60 kg satellite which is able to measure the E-sail effect in the solar wind with four 1 km long tethers. The satellite is mainly built by the Alta space company in Italy.

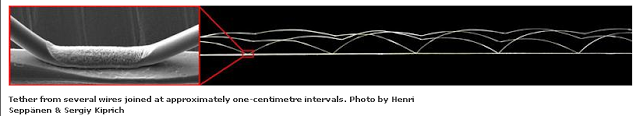

A single metal wire is not suitable as an ESAIL tether, as micrometeoroids present everywhere in space would soon cut it. Therefore the tether must be manufactured from several wires joined together every centimetre [Image 1]. In this way, micrometeoroids can cut individual wires without breaking the entire tether.

The tether factory has so far produced ultrasonic welds for one kilometre of aluminium tether

The Electronics Research Laboratory team started studying the production problem four years ago. At the time, the view of international experts in ultrasonic welding was that joining thin wires together was not possible. However, the one-kilometre-long tether produced now, featuring 90,000 ultrasonic welds, shows that the method works and that producing long electric sail tethers is possible.

The wire is produced with a fully automated tether factory, a fine mechanical device under computer control, developed and constructed by the team itself. [Image 2]. The tether factory at the Kumpula Science Campus in Helsinki, Finland, was integrated into a modified commercial ultrasonic welding device. Ultrasonic welding is widely in the electronics industry, but normally it is used for joining a wire to a base.

-We have a challenging task, as keeping thin wires repeatedly in the precisely correct position is hard, says Timo Rauhala who works in the laboratory.

Approximately three metres of tether is currently produced per hour. Its quality is verified optically with a real-time measurement that inspects the connection of every individual joint. In the future, the production speed is to be raised and the weld quality will be assured during the production process.

The products of the tether factory will soon see action in space. The first opportunity will be the ESTCube-1 satellite, an Estonian small satellite to be launched in March 2013. ESTCube-1 will deploy a 15-metre long tether in space and measure the ESAIL force it is subjected to. This is ground-breaking as, so far, the theoretically predicted electric sail force has not yet been experimentally measured.

Next in turn will be the Aalto-1 small satellite from the Aalto University, to be launched in 2014, which will deploy a 100-metre long tether.

The deployed tethers are kept straight in space by the centrifugal force, the magnitude of which is five grams in a full-scale electric sail. The wire-to-wire welds of the ESAIL tether produced at the University of Helsinki will tolerate a pull of 10 grams.

More information:

http://www.electric-sailing.fi

http://www.estcube.eu

https://wiki.aalto.fi/display/SuomiSAT/Etusivu

SOURCE – alphagalileo.org

Potential of the ESail

We had previously looked at an asteroid capture analysis using solar electric power. The analysis involved a 40 KW solar electric system using an ion thruster (2.4 Newton of power for up to 10,000 hours). They described capturing a 10 ton asteroid to low earth orbit or a 508 ton asteroid to high earth orbit. A near term increase in the ion system can get to 400 KW and 24 Newtons which would enable capturing asteroids ten times as large.

Here is an eight page analysis of Moving an asteroid with electric solar wind sail. The analysis is mainly for deflecting a 3 million ton asteroid over 5 to 10 years.

The E-Sail mass is expected to only weigh in the range of hundreds of kilograms, hence the E-Sail is 100 – 1000 times more efficient than traditional techniques. To produce the same total impulse one would need 100 tons of chemical fuel (specific impulse 300 s) or 10 tons of ion engine propellant (specific impulse 3000 s). Instead of a 13 ton launch of one solar electric propulsion system, one could launch fifty or one hundred of the E-Sails which could combine towing to provide 50 Newtons of towing capacity. The E-Sails would be able to capture 20 to 40 times the mass of asteroids for equivalent launches. Also, the E-Sails can be used repeatedly if there is a long term power source for the electron gun, they would not have other consumables and could keep capturing the solar wind.

Background on the ESail

Nextbigfuture has a dedicated electric sail label where all electric sail articles are collected

We have had extensive coverage of the solar electric sail and the planned test projects.

The Electric Solar Wind Sail (E-sail) was invented by Pekka Janhunen, Finnish Meteorological Institute. He first published “Electric sail for spacecraft propulsion” in the AIAA Journal of Propulsion and Power. (2004)

* Uses solar wind momentum for producing thrust

* Consists of a number of long thin conducting tethers

* An electron gun is used to keep the wires at high positive potential

* The electric field of the wires extends tens of meters into the surrounding solar wind plasma

There is now more details of the first ESTCube-1 space mission to deploy a ten meter solar electric sail wire. It will be followed by a 100 meter test in 2014 and then a satellite with 4 – one kilometer long solar electric sail wires.

* Test of a 100 m tether deployment on Aalto-1 3U CubeSat (2014)

* CubeSat mission to the solar wind

ESTCube -1

* To deploy and confirm the deployment of a 10 m conductive Hoytether from a 1U CubeSat

* To measure the electric sail force, interacting with the tether. The success criteria for this objective is the measured effect on the satellite attitude resulting from electric sail force

Launch planned for 2013

The E-Sail uses charged tethers to extract momentum from the solar wind particles to obtain propulsive thrust. According to current estimates, the E-Sail is 2-3 orders of magnitude better than traditional propulsion methods (chemical rockets and ion engines) in terms of produced lifetime-integrated impulse per propulsion system mass.

A typical E-Sail powered spacecraft might weight 200 kg and have 100 charged tethers, each of 20 km in length. The sail tethers are themselves knitted out of four 25−50μm diameter metal wires in a crossed “Hoytether” pattern in order to minimise the possible destructive effects of micrometeoroids cutting a vulnerable single wire (Hoyt and Forward, 2001). These tethers, if made out of aluminium (2.7 g/cm3) wires, would weigh less than 30 kg for the whole E-Sail. Here the central 25μm wires are assumed to have a 30 angle with respect to the bordering 50μm wires. With 70 kg reserved for the mass of the spacecraft bus, electron gun, solar panels and other E-Sail system parts, one would be left with a payload of 100 kg. With other tether materials of lower density or thickness, the mass taken by the wires can be significantly reduced or the length of the wires risen to produce more force for the same mass. Newest results show that the force produced by the solar sail is five times larger than what was estimated at first, 500 nN/m (Janhunen, 2009). For our default E-Sail this would amount to a force of about 1 N.

Enlarging the size of one E-Sail would directly transfer into higher towing force. The maximum length achieved with normal metals used as E-Sail tether wires is around 100 km, beyond which both the resistivity of the wire and its tensile strength might become an issue. Greater lengths might be achieved with novel materials having much improved strength and lower density when compared to the copper considered here. 100 km long tethers would produce five times the tow of our default sail with 20 km long tethers. Tethers could also be spaced in higher angular density, for example 200 tethers around the sail instead of the default 100 proposed, again roughly doubling the tow. The steering of high number of such a long wires could be problematic though. It might even be possible to upgrade the E-Sail force up to hundreds of Newton’s and even beyond, which would make the E-Sail technology very attractive for various other uses as well as for towing bigger asteroids.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.