Monash University researchers have established, for the first time, an effective way of forming graphene, which normally exists in very thin layers, into useful three-dimensional (3D) forms by mirroring the structure of cork.

Graphene is formed when graphite is broken down into layers one atom thick. In this form, it is very strong, chemically stable and an excellent conductor of electricity. It has a wide range of potential applications, from batteries that are able to recharge in a matter of seconds, to biological tissue scaffolds for use in organ transplant and even regeneration.

Professor Li, from the Department of Materials Engineering, said previous research had focused mainly on the intrinsic properties and applications of the individual sheets, while his team tackled the challenge of engineering the sheets into macroscopically-useable 3D structures.

“When the atomic graphene sheets are assembled together to form 3D structures, they normally end up with porous monoliths that are brittle and perform poorly,” Professor Li said.

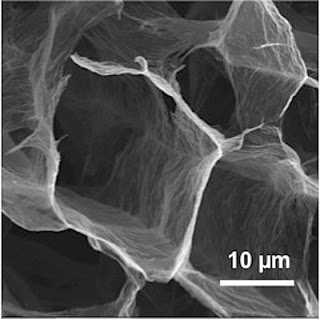

Scanning electron microscope image of cork-like cellular graphene monolith, magnified 2000 times. Credit: Ling Qiu

The graphene monoliths show much lower density then other conventional materials.

Nature Communications – Biomimetic superelastic graphene-based cellular monoliths

“It was generally thought to be highly unlikely that graphene could be engineered into a form that was elastic, which means it recovers well from stress or pressure.”

The researchers used cork, which is lightweight yet strong, as a model to overcome this challenge.

PhD student, Ling Qiu, also from the Department of Materials Engineering, said modern techniques have allowed scientists to analyse the structure of such materials and replicate nature’s efficient design.

“The fibres in cork cell walls are closely packed to maximise strength and individual cells connect in a honeycomb structure which makes the material very elastic,” Mr Qiu said.

Using a method called freeze casting, the researchers were able to form chemically modified graphene into a 3D structure that mimicked cork. The graphene blocks produced were lighter than air, able to support over 50,000 times their own weight, good conductors of electricity and highly elastic – able to recover from over 80 per cent deformation.

“We’ve been able to effectively preserve the extraordinary qualities of graphene in an elastic 3D form, which paves the way for investigations of new uses of graphene – from aerospace to tissue engineering,” Professor Li said.

“Mimicking the structure of cork has made possible what was thought to be impossible.”

ABSTRACT – Many applications proposed for graphene require multiple sheets be assembled into a monolithic structure. The ability to maintain structural integrity upon large deformation is essential to ensure a macroscopic material which functions reliably. However, it has remained a great challenge to achieve high elasticity in three-dimensional graphene networks. Here we report that the marriage of graphene chemistry with ice physics can lead to the formation of ultralight and superelastic graphene-based cellular monoliths. Mimicking the hierarchical structure of natural cork, the resulting materials can sustain their structural integrity under a load of over 50,000 times their own weight and can rapidly recover from over 80% compression. The unique biomimetic hierarchical structure also provides this new class of elastomers with exceptionally high energy absorption capability and good electrical conductivity. The successful synthesis of such fascinating materials paves the way to explore the application of graphene in a self-supporting, structurally adaptive and 3D macroscopic form.

Energy loss coefficients of graphene monoliths and other ultralight materials at first compressive cycle (value is calculated from the compressive stress-strain curve). Graphene monoliths show higher energy loss coefficient than other materials

13 pages of supplemental information

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.