Technology Review – IMEC has developed a way to put integrated circuits into flexible and stretchable materials without impairing the microchip’s functionality. The technique could lead to more sophisticated biomedical implants or electronics embedded in clothing.

Jan Vanfleteren, an electrical engineer at the Interuniversity Micro Electronics Centre at the University of Ghent, in Belgium, has developed a new approach. It involves “thinning” an off-the-shelf microchip from 725 micrometers down to just 30 micrometers using a conventional grinding process. Vanfleteren says the process does not impair the performance of the microchip.

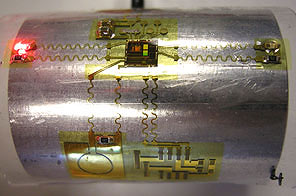

Wrap around: This “thinned-down” flexible microprocessor is connected via stretchable copper interconnects, all using conventional materials.

IMEC

The chips are processed while still on the wafer from which they are cut, embedded within a thin substrate, and then connected to other components embedded within the plastic via a stretchable copper interconnect.

Vanfleteren presented a prototype flexible microcontroller at the Electronics and System Integration Technology Conference in Amsterdam last month. It can be stretched beyond 50 percent of its length (20 percent is sufficient for a biomedical device), and can be flexed 10,000 to 100,000 times before breaking. It is even machine washable, Vanfleteren notes, making it suitable for clothing.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.