Eurekalert – A team of Boston College and MIT researchers report developing a novel, nanotech design that boosts the thermoelectric performance of a bulk alloy semiconductor by 30 to 40 percent above its previously achieved figure of merit, the measuring stick of conversion efficiency in thermoelectrics. The optimally doped matrix and could already compete with the state-of-the-art n-type Si80Ge20P2 thermoelectric bulk materials with a much lower materials cost. To further improve the modulation-doping approach, using a thin spacer layer to minimize the diffusion would be expected to further improve the measured performance.

The alloy in question, Silicon Germanium, has been valued for its performance in high-temperature thermoelectric applications, including its use in radioisotope thermoelectric generators on NASA flight missions. But broader applications have been limited because of its low thermoelectric performance and the high cost of Germanium.

Boston College Professor of Physics Zhifeng Ren and graduate researcher Bo Yu, and MIT Professors Gang Chen and Mildred S. Dresselhause and post-doctoral researcher Mona Zebarjadi, report in the journal Nano Letters that altering the design of bulk SiGe with a process borrowed from the thin-film semiconductor industry helped produce a more than 50 percent increase in electrical conductivity.

While long valued for high-temperature applications, the bulk alloy semiconductor SiGe hasn’t lent itself to broader adoption because of its low thermoelectric performance and the high cost of Germanium. A novel nanotechnology design created by researchers from Boston College and MIT has shown a 30 to 40 percent increase in thermoelectric performance and reduced the amount of costly Germanium. Credit: Nano Letters

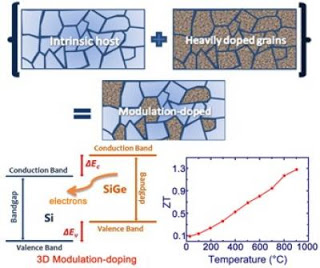

The process, known as a 3D modulation-doping strategy, succeeded in creating a solid-state device that achieved a simultaneous reduction in the thermal conductivity, which combined with conductivity gains to provide a high figure of merit value of ~1.3 at 900 °C.

“To improve a material’s figure of merit is extremely challenging because all the internal parameters are closely related to each other,” said Yu. “Once you change one factor, the others may most likely change, leading to no net improvement. As a result, a more popular trend in this field of study is to look into new opportunities, or new material systems. Our study proved that opportunities are still there for the existing materials, if one could work smartly enough to find some alternative material designs.”

Ren pointed out that the performance gains the team reported compete with the state-of-the-art n-type SiGe alloy materials, with a crucial difference that the team’s design requires the use of 30 percent less Germanium, which poses a challenge to energy research because of its high cost. Lowering costs is crucial to new clean energy technologies, he noted.

“Using 30 percent less Germanium is a significant advantage to cut down the fabrication costs,” said Ren. “We want all the materials we are studying in the group to help remove cost barriers. This is one of our goals for everyday research.”

Modulation-doping was theoretically proposed and experimentally proved to be effective in increasing the power factor of nanocomposites (Si80Ge20)70(Si100B5)30 by increasing the carrier mobility but not the figure-of-merit (ZT) due to the increased thermal conductivity. Here we report an alternative materials design, using alloy Si70Ge30 instead of Si as the nanoparticles and Si95Ge5 as the matrix, to increase the power factor but not the thermal conductivity, leading to a ZT of 1.3 ± 0.1 at 900 °C.

The research groups list of publications

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.