1. Biologically-derived Medicines on Demand

The Bio-MOD program seeks to develop devices and techniques to produce multiple protein biologics in response to specific battlefield threats and medical needs. This will be achieved by investing in

(1) novel, flexible methodologies for genetic engineering/modification of microbial strains, eukaryotic strains, and/or cell-free systems to synthesize multiple protein-based therapeutics; and

(2) flexible and portable device platforms for manufacturing multiple biologics with high purity, efficacy and potency at the point-of-care, in short timeframes, when the specific need arises.

Consequently, Bio-MOD will provide a battlefield medical supply for military medics at the front lines of support that is responsive to far-forward emergency settings and emergent in-theater needs.

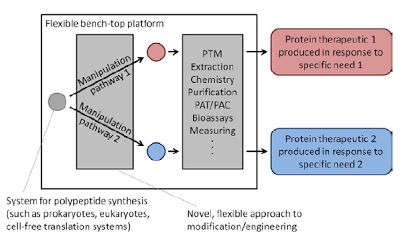

Universal schematic for the Phase 1 Bio-MOD system that incorporates a novel, flexible engineering approach to genetically manipulate single strains of prokaryotic cells, eukaryotic cells, or cell-free systems to produce multiple protein therapeutics in a bench-top platform. Diagram does not indicate a preferred design, but rather illustrates the overall vision of the Bio-MOD program.

Technical Area One: New, Flexible approaches to Manipulating Polypeptide Synthesis Systems

Bio-MOD requires new and flexible approaches for manipulating and engineering polypeptide synthesis systems (such as prokaryotes, eukaryotes, and cell-free translation systems) at genetic and/or cellular levels to produce multiple therapeutics in response to specific demands. Proposers can use multiple strains to produce separate biologics if there is a compelling reason to do so; however, engineering of single strain approaches are preferred because they will conceivably be more readily expandable to address additional/emerging needs. Engineering of single prokaryotic and eukaryotic strains might include genetic modification of common genetic regulatory, metabolic, and cellular pathways that produce unique proteins for a given stimuli. Example approaches include, but are not limited to, nutrient activation where nutrient type/concentration triggers specific therapeutic output, photoactivation where light intensity/wavelength inputs trigger therapeutic output, and pH activation where pH of solution triggers therapeutic output.

The final Bio-MOD system must incorporate the entire synthetic process from initial steps to final, appropriately pure, efficacious and potent protein-based therapeutic at an effective dose. If the main protein output of the engineered system is a precursor, additional processing must be developed to transform the precursor to the final therapeutic. Detailed plans for PTM, extraction, chemical modification, separation, purification, and other processes that are required to complete the production process in the final bench-top platform and in initial in vitro studies must be provided.

Technical Area Two: Flexible and Portable Platform

Bio-MOD requires development of a protein production platform that is both flexible (multiple therapeutics can be produced based on specific demands) and portable (device size can range from hand-held to bench-top). Accordingly, proposals to the program must identify and provide detailed designs for all key components of the proposed system. These potentially include, but are not limited to, bioreactors, PTM, extraction, chemical modification, separation, purification, process analytical technologies (PAT), process analytical chemistry (PAC), high throughput screening technologies, biological assays, informatics and process control, measuring, and output dosing. Proposals must also include a comprehensive plan for integration of these components. Key components can be Commercial-Off-The-Shelf systems or can be custom designed. Exact sizes for portable bench-top systems are not specified by DARPA, but platform size must be estimated in proposals. The correlation between size and capability of the device will be considered; for example, more tolerance will be given to larger size if it is a more capable system and vice-versa. Bio-MOD requires a breadboard layout to be developed for the bench-top system in Phase 1, and a completed, integrated device approved by the FDA by the end of Phase 2. The proposal must provide a comprehensive plan for Phase 2 development of the completed, fully integrated platform. A laboratory approach (using conventional equipment not incorporated into the platform design) for protein synthesis, analysis/characterization, separation, purification, etc. can be pursued in parallel to platform development. This will allow Phase 1 to be focused on molecular biology and the device build while not setting impossible device development goals at the outset of the program.

Additional Bio-MOD Requirements

Therapeutics to be pursued in the program are not specified by DARPA; however, they must be protein-based biologics previously approved by the FDA (i.e., therapeutic discovery is specifically excluded from Bio-MOD), and must be widely applicable and relevant to the Department of Defense (DoD) and to national security. Examples of DoD-relevant and national security-relevant protein-based therapeutics include, but are not limited to:

• Erythropoietin, Epoetin-a

• Recombinant Interferon

• Tissue plasminogen activator (tPA)

• Factor VIIa

• Drotrecogin-a, activated protein C

• Trypsin

• Collagenase

• Papain

• Streptokinase

• Recombinant purified protein derivative (DPPD)

Proposers must identify the therapeutics they aim to produce, and must provide evidence of wide applicability and relevance to the DoD.

DARPA is soliciting innovative multidisciplinary research proposals to develop and demonstrate synthesis methods of materials with superior properties (over 1.5X over SOA) that currently can only be made using ultrahigh pressure techniques, such that processing under conditions amenable to production scales (less than 2000 K and 0.5 GPa) and stability under ambient conditions is achieved. Extended solids are polymorphs/phases of simple molecules that are currently formed under ultrahigh pressure conditions where strong intermolecular bonding and tight crystal packing can be induced, leading to dramatic changes in physical, mechanical, and functional properties.

Background/Vision

Development of synthesis pathways and processing methodologies for virtually all chemicals and materials now in use has been achieved by manipulating constituent ingredients and reaction temperatures. Historically, the effects of pressure have largely not been exploited, and even now, bulk material processing is limited to pressures less than 0.5 GPa. Recent scientific advances in computational physics/chemistry, experimental geophysics/high pressure chemistry, and high resolution diagnostics have opened up a new, extremely large, material design space in the ultrahigh pressure regime (up to 300 GPa). Under these ultrahigh pressure conditions, strong intermolecular bonding and tight crystal packing can be induced, leading to the formation of new material polymorphs or phases with dramatic changes in physical, mechanical, and functional properties. These materials are known as extended solids. High pressure polymorphs/phases of metals, intermetallics, oxides, nitrides, carbon, and even simple gaseous molecules, such as CO2, CO, N(H)x, CN, and others have been identified. A number of these materials have high pressure polymorphs/phases that exhibit superior structural (high strength, high thermal conductivity), energetic (propellant) and functional (e.g., ferroelectric, magnetic, optical) properties.

Unfortunately, in all of these cases, the very high pressures currently required to produce these materials limit the amounts that can be made to the microgram scale. Although these quantities are sufficient to conduct initial academic studies, they are inadequate to develop materials that can be used to enhance performance of DoD systems. The overall goals of this program are both to determine the potential that extended solids bring to the materials community by identifying materials that have significantly enhanced properties over materials that are currently available and to develop methods for stabilizing and scaling up selected materials to enable their exploitation in Department of Defense (DoD) applications.

The vision of this program is to develop methods that permit access to these ultrahigh pressure polymorphs/phases without having to go to the ultrahigh pressures currently required. In the thermochemical regime, the ability to synthesize the vast array of available materials, both biochemically and synthetically, is predicated on the exploitation of multistep synthesis and stabilization strategies, so that target materials can be produced via intermediates using methods and conditions mild enough to be viable. This program seeks development and demonstration of analogous strategies that can be applied to the barochemistry (ultrahigh pressure) regime. Development of this technology could fundamentally change the way high pressure polymorphs/phases are synthesized, opening a vast new material design space to exploitation.

Over the past decade, there have been enormous advances in: (i) computational capabilities that permit accurate simulation and prediction of material properties and response as a function of constituents, intermolecular configuration / conformation, and internal energy – both thermal and mechanical; (ii) efficient search algorithms that will permit mapping of these “energy landscapes” allowing for identification of extended metastable structures and potential lower pressure pathways leading to them; and (iii) experimental characterization methods, including x-ray, spectroscopic, acoustic, and photonic, that can be applied in the ultrahigh pressure regime capable of characterizing microstructural features at the lattice length scale, and to determine physical, chemical, mechanical, functional properties. In fact, the ability to significantly reduce the pressure required to achieve the synthesis of a high pressure phase has been very recently demonstrated experimentally, by forming an intermediate stable phase, which when again subjected to pressure undergoes conversion to the target high pressure phase.

The confluence of these emerging capabilities makes it possible to apply novel strategies to the discovery, development and bulk fabrication of high pressure extended solids with properties radically superior than their ambient pressure precursors. The DoD as well as commercial applications of extended solids are pervasive, and is expected to result in breakthrough improvements in strength, stiffness, energy content, thermal conductivity, electromagnetic, optical properties etc., with concomitant performance improvements in a wide range of specific DoD applications ranging from armor to propulsion to aerospace, ground, and naval platforms.

To realize this vision, focused, interdisciplinary research efforts by investigators with the skills needed to address all of the relevant research challenges will be necessary. These fields could include, but are not limited to high pressure physics and chemistry, computational chemistry, material property computation, materials property testing, and new manufacturing techniques. It will be essential to take innovative, integrated approaches, with creative use of recent scientific advances to successfully develop, implement and demonstrate the capability to address such an ambitious challenge. This program seeks to do so by drawing from these diverse research communities to cultivate collaboration among research teams focused on adaptation and application of these emerging capabilities to develop and demonstrate radically new material design methodologies.

Research Areas

The goal of the Extended Solids program is to enable scalable production of high pressure polymorphs/phases of materials that exhibit mechanical, functional, or energetics properties that are unachievable today. Properties sought include, but are not limited to, high hardness, energy content, thermal conductivity, electromagnetic, and optical; and where substantial (over 50%) improvement in performance in DoD (such as armor, propellant, high temperature, and other) applications may be achieved. Proposed research should investigate innovative approaches that enable revolutionary advances in science, devices, or systems. This will require development of processing methods and stabilization techniques that allow extended solids to be stable at ambient pressures and temperatures. This includes identification of possible additives and techniques to enable synthesis of these materials at lower pressures and in bulk (monolithic) amounts.

The Extended Solids Program has three technical areas of interest. Since a comprehensive, integrated solution is desired, proposals are expected to address all three technical areas. Proposals that do not address all three areas will be considered non-responsive.

Technical Area One: Development and implementation of computational techniques to assist in discovery, stabilization and synthesis of high pressure polymorphs/phases with superior properties. The goal for this area is to efficiently map “energy landscapes” that elucidate the relationship between molecular structure, intermolecular (lattice) structure, pressure, temperature and stability. This will be applied to the identification and description of any intermediates that will enable design of reduced pressure, multistep synthetic pathways to target materials. They will also be able to predict the kinetics of phase transitions at various pressures and temperatures and suggest material processing strategies, which may include multistep techniques that result in the low pressure synthesis of the desired materials.

Technical Area Two: Synthesis and stabilization of intermediates and extended solid polymorphs/phases to room temperature and pressure. The goal for this area is to ensure that the materials produced are useful (i.e. stable) at ambient and standard operating temperatures and pressures. A variety of techniques such as alloying, doping, complexation, lattice pinning, and surface functionalizing, may be used to achieve this goal as long as they do not significantly attenuate the desired superior material property.

Technical Area Three: Reduced pressure synthesis, scale-up and demonstration of properties of extended solid polymorphs/phases. The goal for this area is to ensure the target materials can be produced using large-scale presses (or alternate methods) as monoliths, and therefore have the potential to be transitioned into DoD applications programs. A variety of strategies could be used to achieve this goal such as the use of templates, processing matrices and multistep synthetic pathways as long as they do not significantly attenuate the desired superior material property.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.