The UK has about 87 tonnes of plutonium extracted from nuclear fuel used in reactors that were built as part of a national program that ran from the 1950s to the 1990s. The fuel continues to build up and stocks will hit 140 tonnes by 2018.

GE-Hitachi say the option of using two Prism reactors is attractive because they would generate 600 MWe of electricity while conditioning and disposing of the stocks.

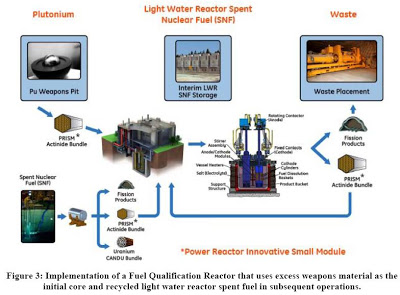

The PRISM (Power Reactor Innovative Small Modular) is GE Hitachi Nuclear Energy’s next generation sodium-cooled fast neutron reactor.

Today’s PRISM is a GE-Hitachi design for compact modular pool-type reactors with passive cooling for decay heat removal. After 30 years of development it represents GEH’s Generation IV solution to closing the fuel cycle in the USA. Each PRISM Power Block consists of two modules of 311 MWe each, operating at high temperature – over 500°C. The pool-type modules below ground level contain the complete primary system with sodium coolant. The Pu & DU fuel is metal, and obtained from used light water reactor fuel. However, all transuranic elements are removed together in the electrometallurgical reprocessing so that fresh fuel has minor actinides with the plutonium. Fuel stays in the reactor about six years, with one third removed every two years. Used PRISM fuel is recycled after removal of fission products. The commercial-scale plant concept, part of a Advanced Recycling Centre, uses three power blocks (six reactor modules) to provide 1866 MWe.

Prism would be part of a complete fuel reprocessing system The (Advanced Recycling Cneter) ARC would cut radioactive waste. It could extract/burn by up to 90 percent of the energy in uranium, instead of the 2-3 percent that widely-used light water reactors do.

The main part of construction of the ACME facility is scheduled to be completed by mid-2012, while the test data analysis and code assessment are planned to be finished at the end of 2013.

In addition to the passive core cooling system testing facility, several other CAP1400 test facilities, including an integrated test facility for the passive containment cooling system, are also being established.

Construction of the first CAP1400, at a site near Weihei in Shandong Province, is officially scheduled to begin in April 2013. SNPTC will take the lead with 55% of the project company. The other stakeholder will be Huaneng Nuclear Power Development Corp, a subsidiary China Huaneng Group, one of China’s largest power companies. The partners hope their first CAP1400 will begin operation in December 2017. The pressurized water reactor is a development of a Westinghouse design currently being imported with its generating capacity boosted from 1100 MWe to 1400 MWe.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.