NSF.gov – Researchers at the University of Massachusetts Amherst employed photographic techniques and polymer science to develop a new technique for printing two-dimensional sheets of polymers that can fold into three-dimensional shapes when water is added. The technique may lead to wide ranging practical applications from medicine to robotics.

The technique could be used to direct growth of blood vessels or tissues in the laboratory.

Researchers used a photomask and ultraviolet (UV) light to “print” a pattern onto a sheet of polymers, a technique called photolithography. In the absence of UV exposure, the polymer will swell and expand uniformly when exposed to water, however when polymer molecules within the sheet were exposed to UV light they became crosslinked–more rigidly linked together at a number of points–which prevented them from expanding when water was added. Patterning the amount of crosslinking across an entire sheet allowed researchers to control how much each area swelled. A second exposure to a carefully selected pattern of UV light allowed them to create specific 3-D shapes.

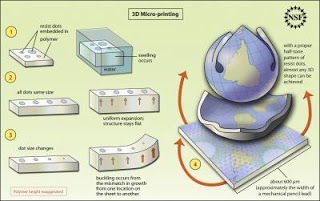

Controlling growth in a polymer system at the micro-scale with a technique akin to half-tone printing, the polymer swells like a sponge when exposed to water. Printing “resist dots” in the polymer substrate creates points that will not swell. When the dot size changes, buckling occurs from the mismatch in growth from one area to another. With a proper half-tone pattern of resist dots, almost any 3-D shape can be achieved. (Credit: Zina Deretsky, National Science Foundation)

Science – Designing Responsive Buckled Surfaces by Halftone Gel Lithography

Self-actuating materials capable of transforming between three-dimensional shapes have applications in areas as diverse as biomedicine, robotics, and tunable micro-optics. We introduce a method of photopatterning polymer films that yields temperature-responsive gel sheets that can transform between a flat state and a prescribed three-dimensional shape. Our approach is based on poly(N-isopropylacrylamide) copolymers containing pendent benzophenone units that allow cross-linking to be tuned by irradiation dose. We describe a simple method of halftone gel lithography using only two photomasks, wherein highly cross-linked dots embedded in a lightly cross-linked matrix provide access to nearly continuous, and fully two-dimensional, patterns of swelling. This method is used to fabricate surfaces with constant Gaussian curvature (spherical caps, saddles, and cones) or zero mean curvature (Enneper’s surfaces), as well as more complex and nearly closed shapes.

They say the technique, among other applications, may someday help biomedical researchers to direct cells cultured in a laboratory to grow into the correct shape to form a blood vessel or a particular organ.

“We wanted to develop a strategy that would allow us to pattern growth with some of the same flexibility that nature does,” Hayward explains. Many plants create curves, tubes and other shapes by varying growth in adjacent areas. While some leaf or petal cells expand, other nearby cells do not, and this contrast causes buckling into a variety of shapes, including cones or curly edges. A lily petal’s curve, for example, arises from patterned areas of elongation that define a specific three-dimensional shape.

Building on this concept, Hayward and colleagues developed a method for exposing ultraviolet-sensitive thin polymer sheets to patterns of light. The amount of light absorbed at each position on the sheet programs the amount that this region will expand when placed in contact with water, thus mimicking nature’s ability to direct certain cells to grow while suppressing the growth of others. The technique involves spreading a 10-micrometer-thick layer (about 5 times thinner than a human hair) of polymer onto a substrate before exposure.

Areas of the gel exposed to light become crosslinked, restricting their ability to expand, while nearby unexposed areas will swell like a sponge as they absorb water. As in nature, this patterned growth causes the gel to buckle into the desired shape. Unlike in nature, however, these materials can be repeatedly flattened and re-shaped by drying out and rehydrating the sheet.

To date, the UMass Amherst researchers have made a variety of simple shapes including spheres, saddles and cones, as well as more complex shapes such as minimal surfaces. Creating the latter represents a fundamental challenge that demonstrates basic principles of the method, Hayward says.

He adds, “Analogies to photography and printing are helpful here.” When photographic film is exposed to patterns of light, a chemical pattern is encoded within the film. Later, the film is developed using several solvents that etch the exposed and unexposed regions differently to provide the image we see on the photographic negative. A very similar process is used by UMass Amherst researchers to pattern growth in gel sheets.

Santangelo and Hayward also borrowed an idea from the printing industry that allows them to make complicated patterns in a very simple way. In photolithography, just as in printing, it is expensive to print a picture using different color shades because each shade requires a different ink. Thus, most high-volume printing relies on “halftoning,” in which only a few ink colors are used to print varied-sized dots. Smaller dots take up less space and allow more white light to reflect from the paper, so they appear as a lighter color shade than larger dots.

An important discovery by the UMass Amherst team is that this concept applies equally well to patterning the growth of their gel sheets. Rather than trying to make smooth patterns with many different levels of growth, they were able to simply print dots of highly restricted growth and vary the dot size to program a patterned shape.

“We’re discovering new ways to plan or pattern growth in a soft polymer gel that’s spread on a substrate to get any shape you want,” Santangelo says. “By directly transferring the image onto the soft gel with half-tones of light, we direct its growth.”

He adds, “We aren’t sure yet how many shapes we can make this way, but for now it’s exciting to explore and we’re focused on understanding the process better. A model system like this helps us to watch how it unfolds. For biomedicine or bioengineering, one of the questions has been how to create tissues that could help to grow you a new blood vessel or a new organ. We now know a little more about how to go from a flat sheet of cells to a complex organism.”

RSC Chemistry World – Polymer chemists have successfully emulated the natural shape-shifting abilities of biological tissues, which could allow them to develop a new range of functional materials that change shape reversibly in response to particular stimuli. Such materials would have applications in areas as diverse as biomedicine, robotics, tuneable micro-optics and tissue engineering.

7 pages of supporting material

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.