Particulates (PM10 – 10 micron and PM 2.5 2.5 micron) are the main pollutant, along with sulfur dioxide (smog) and Nitrogen oxides that cause the main health issues.

Economics of retrofit air pollution

control technologies The technology is many orders of magnitude cheaper than carbon sequestration for dealing with carbon dioxide and would save more lives.

Legislation in the USA has resulted in the installation of air pollution control technology such as selective catalytic reduction (SCR) for NOx removal and wet FGD scrubbing for SO2 control on many plants. Some plants were allowed to not install that technology. All plants should be required to install those systems.

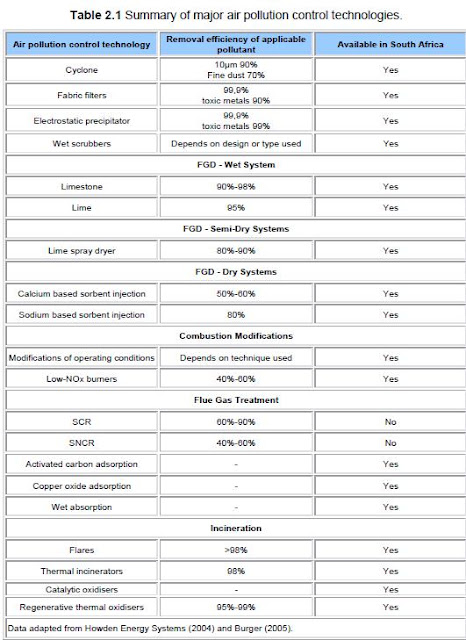

There are many technologies available for reducing air pollutant emissions from existing pulverised coal-fired power plant (including nitrogen oxides (NOx), particulate matter (PM), sulphur dioxide (SO2) and mercury (Hg)).

The particulate control technology costs about $50,000,000 per 1 gigawatt coal plant to achieve 99-99.5% reduction in particulates. A total of about $400 million for the more effective air pollution technologies for Sulfur dioxide, nitrogen oxides and particulates.

So it is perfectly feasible and economic to retrofit existing coal plants to prevent most of the air pollution and the damage that they cause. The costs is far less than what is required to deal with carbon dioxide (pipes to capture and put it all into large places underground).

China has about 650 GWe of coal power installed in 2011. It would probably be cheaper for China to do the particulate retrofits (say $30 million per GWe). Therefore $20 billion would enable a 99.5% reduction in particulates. The United States has 315 GWe of coal power installed in 2011. It would cost about $16 billion for electrostatic precipitators on all coal plants in the United States.

Retrofit technologies assessed and costed in the review for control of emissions of NOx, PM, SO2 and mercury include:

* low NOx combustion systems (low NOx burners (LNB) and overfire air (OFA));

* flue gas treatment (selective catalytic reduction (SCR) and selective noncatalytic

reduction (SNCR));

* particulate control (electrostatic precipitators (ESP) and fabric filters(FF));

* flue gas desulphurisation (FGD) (wet scrubbing, spray dry scrubbing (SDS) and circulating fluid bed (CFB) dry scrubbing);

* sorbent injection for mercury reduction.

Data show capital cost for LNB in the range ~615–7865 $/GJ, operating cost that can vary from around 320–1420 $/GJ and levelised cost can range between 240 and 4300 $/t of NOx removal.

The choice between ESP and fabric filtration generally depends on coal type, plant size and boiler type and configuration. Both technologies are highly efficient particulate removal devices with design efficiencies in excess of 99.5%. The review shows the cost of the different methods to improve/upgrade ESPs and retrofit fabric filters.

FURTHER READING

The dissertation has a cost analysis of air pollution control technology for a 3600 MW coal plant in South Africa. The capital costs were less than half of the benefits in reduced pollution.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.