Ad Support : Nano Technology Netbook Technology News Computer Software

Its compact size will allow ‘2’ T.25’s to travel in one UK motorway lane. Trebling the capacity and reducing congestion.

‘3’ T.25’s can easily fit into ‘1’ standard UK parallel parking space, trebling much needed urban parking, reducing pressures for inner cities as well as the disruption to traffic flow.

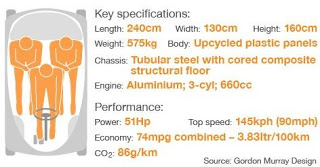

* ultra lightweight by design (approximately 550kg)

* Will still achieve the highest safety standards (at least 4* Euro NCAP).

* has a top speed of almost 100mph and is expected to cost about £6,000 ($9,000).

* there is a T27 electric car with a similar form factor.

* The 30 staff members are secretly developing a number of different vehicles based on the T.25 manufacturing principles. A five-seater, an eight-seater, a bus, or a two-seater.

IStream Factory

Prof Murray has come up with a way of producing cars that does away with the most polluting parts used in conventional factories – such as large stamping presses to make steel body parts, welding robots or paint shops.

“We dig very little steel out of the ground. We use a tiny bit – about 35 euros ($45; £29) worth per car – of low energy mild steel, which is a very low energy process. It’s about 60kg of steel in a T.25. That’s it.” The manufacturing method, called iStream, is incredibly flexible. Modifying the size of the frame or the shape and colour of the body panels can be done simply by rewriting the software, so on the same production line you can have “any body you like, on the same day”, he explains.

And by simply changing the shape of the monocoque, a manufacturer can slot in pretty much any engine, whether a conventional one using petrol or diesel or an electric motor powered by batteries or hydrogen fuel cells.

* Replacing metal presses with machines for bending, welding and the simplified assembly process means that the manufacturing plant can be designed to be 20% the size of a conventional factory. This could reduce capital investment in the assembly plant by approximately 80%.

<>br

* Associated energy savings will significantly reduce operating expense. Simultaneous reductions in greenhouse gas emissions will make compliance with existing and future environmental regulations much easier e.g. reduced requirement to offset emissions via trading schemes and potentially even the sale of surplus credits.

If you liked this article, please give it a quick review on Reddit, or StumbleUpon. Thanks

Supporting Advertising

Business Success

How to Make Money

Executive Jobs

Paid Surveys

Thank You

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.