Ad Support : Nano Technology Netbook Technology News Computer Software

These LHC magnets use cables made of superconducting niobium titanium (NbTi), and for five years during its construction the LHC contracted for more than 28 percent of the world’s niobium titanium wire production, with significant quantities of NbTi also used in the magnets for the LHC’s giant experiments.

Berkeley labs is working with the high-temperature superconductor Bi-2212 (bismuth strontium calcium copper oxide) to develop stronger magnets. In experimental situations Bi-2212 has generated fields of 25 T (tesla) and could go much higher. But like many high-temperature superconductors Bi-2212 is not a metal alloy but a ceramic, virtually as brittle as a china plate.

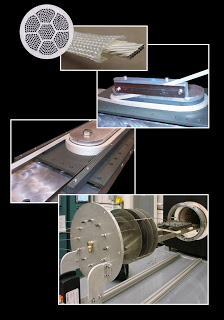

One of the things that makes Bi-2212 promising is that it is now available in the form of round wires.

“The wires are essentially tubes filled with tiny particles of ground-up Bi-2212 in a silver matrix,” Godeke explains. “While the individual particles are superconducting, the wires aren’t – and can’t be, until they’ve been heat treated so the individual particles melt and grow new textured crystals upon cooling – thus welding all of the material together in the right orientation.”

Orientation is important because Bi-2212 has a layered crystalline structure in which current flows only through two-dimensional planes of copper and oxygen atoms. Out of the plane, current can’t penetrate the intervening layers of other atoms, so the copper-oxygen planes must line up if current is to move without resistance from one Bi-2212 particle to the next.

In a coil fabrication process called “wind and react,” the wires are first assembled into flat cables and the cables are wound into coils. The entire coil is then heated to 888 degrees Celsius (888 C) in a pure oxygen environment. During the “partial melt” stage of the reaction, the temperature of the coil has to be controlled to within a single degree. It’s held at 888 C for one hour and then slowly cooled.

Silver is the only practical matrix material that allows the wires to “breathe” oxygen during the reaction and align their Bi-2212 grains. Unfortunately 888 C is near the melting point of silver, and during the process the silver may become too soft to resist high stress, which will come from the high magnetic fields themselves: the tremendous forces they generate will do their best to blow the coils apart. So far, attempts to process coils have often resulted in damage to the wires, with resultant Bi-2212 current leakage, local hot spots, and other problems.

The goal of the program to develop Bi-2212 for high-field magnets is to improve the entire suite of wire, cable, coil making, and magnet construction technologies. We need to improve current density by a factor of three or four.

The Large Dipole test magnet, called LD1, will be used to test magnets and wires. The test magnet will be based on niobium-tin technology and will exert a field of up to 15 T across the height of the aperture. Inside the aperture, two cable samples will be arranged back to back, running current in opposite directions to minimize the forces generated by interaction between the sample and the external field applied by LD1.

The magnets are being developed to make the highest-energy colliders possible. The new technology will benefit many other fields as well, from undulators for next-generation light sources to more compact medical devices.

If you liked this article, please give it a quick review on Reddit, or StumbleUpon. Thanks

Supporting Advertising

Business Success

How to Make Money

Executive Jobs

Paid Surveys

Thank You

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.