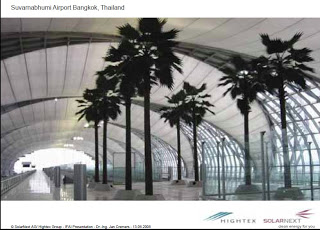

A presentation included pictures of the Bangkok airport and how they use a fabric cover to reflect sunlight and control the temperature beneath it.

This structure was made of PTFE and glass but the principles would still apply for ETFE and other materials. The shape of the structure traps more of the heat near the roof and enables the floor and bottom half to be cool. The airport structure covers about 1 million square feet which is 23 acres.

Suvarnabhumi Airport has the world’s third largest single-building airport terminal (563,000 square metres / 6,060,000 square feet). Only about 16% of it is the fabric cover areas.

Hightex Group plc (AIM:HTIG), a leading designer and installer of large membrane roofs and façades worldwide, is delighted to announce that it has been awarded a contract to supply the entire retractable roof and the fixed façade for the BC Place Stadium in Vancouver, British Columbia, Canada. When completed, this roof will be the largest cable supported retractable roof in the world. The projected area of the retractable portion of the roof is approximately 6,700m², requiring a total of approximately 13,400m² of membrane material.

The new roof is part of the revitalization of the BC Place Stadium, which remains the home of the BC Lions. Once completed, the stadium will also host the first season of the Vancouver Whitecaps as a Major League Soccer Franchise in 2011. The existing pneumatic dome is to be dismantled and replaced with a partially fixed, partially retractable fabric roof as well as a transparent membrane facade.

The new roof substructure consists of a radial cable net and outer steel columns. The fabric roof is divided up into 36 fixed outer panels and 36 inner retractable segments. The outer fixed roof, to be the subject of a separate contract, has an area of about 34,000m². The inner roof will consist of a double layer Tenara membrane with an inflated inter-space to form “cushion” elements. The cushions will be pre-stressed using hydraulic tensioning units and inflation via fan units.

The retractable roof will be connected to the 36 radial cables by specially designed sliding and driving carriages. The deflated cushion will be stored at the centre of the roof in a membrane garage. To close the roof, the driving carriages will pull the membrane outwards radially towards the perimeter. The retractable roof is made of a highly translucent fabric which will allow the fabric to be folded without damage.

The new façade comprises some 6,000m² of transparent membrane panels using ETFE. The facade panels are pre-stressed using metal arches and are attached directly to the primary steel structure.Hightex’s total scope on the project includes the fabrication of the outer roof, fabrication and installation of the retractable roof including drive technology and the fabrication and installation of the ETFE facade.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.