Of the reactors covered here: The Chinese HTR-PM (250 MWe) is scheduled to begin construction in September of this year and is to be completed in 2013. The Hyperion Power Generation company has customer orders and is planning to have their first hot tub size uranium hydride reactors (27MWe) built in 2013. The Russians have built reactors like the SVBR (75/100 MWe) metal breeder reactor for their submarines. The SVBR reactor project is funded and should have a pilot reactor for 2020. These first three reactors would likely also be the lowest cost reactors of the ones proposed here. The funding and commitment to build those reactors seems to be the strongest. China and Russia will build those reactors for internal use. Hyperion Power Generation’s uranium hydride reactor seems simple enough and they have convinced customers to buy it if they build it and can meet what they are claiming.

1. Babcock and Wilcox 150MW Modular LWR

Going nuclear: This illustration shows a 4.5-meter-wide, 23-meter-long nuclear reactor designed to fit on a railcar for shipping to the site of a power plant.

Credit: Babcock and Wilcox

MIT Technology Review: A new type of nuclear reactor that is designed to be manufactured in a factory rather than built at a power plant could cut construction times for nuclear power plants almost in half and make them cheaper to build. That, in turn, could make it possible for more utilities to build nuclear power plants, especially those in poor countries. The design comes from Babcock and Wilcox, a company based in Lynchburg, VA, that has made nuclear reactors for the United States Navy ships for about 50 years.

Christofer Mowry, CEO of Babcock and Wilcox, estimates that total construction time will be three years–at least two years less than conventional construction would take. The design also avoids a bottleneck in conventional (light water reactors) nuclear power plant construction, which is that the large reactor vessel–a pressurized chamber containing the reactor core and necessary coolant. Mowry says that Babcock and Wilcox plans to file the official certification application in 2011. The company is already working with the Tennessee Valley Authority to start the process of evaluating a site for a plant that would use the reactor technology. Mowry says that the first plants using the technology could be up and running by 2018. But Mujid Kazimi, another professor of nuclear engineering at MIT, says that goal sounds “very ambitious” given what’s known about the regulatory process.

Dan Yurman, Idaho Samizdat blog, has coverage.

At the Babcock and Wilcox press conference, they said they hope to sign a contract with the first customer by 2011 and have one in revenue service by 2018. At an estimated $4,000/Kw, a number cited by the firm in press interviews, a unit would cost $500 million.

2. Nuscale is a startup that is working towards making 40 MW modular light water reactors.

Because of the modular and scalable design, NuScale anticipates construction timeframes of 30 to 36 months from breaking ground at a site to power generation. Additional modules can then be added as needed. NuScale projects that the first plant can go into operation from 2015 to 2016. Initial pre-application review meeting was held with the NRC in July 2008. NuScale anticipates filing Design Certification application in 2010.

Thermal capacity – 150 Mwt

Electrical capacity – 40 Mwe

Capacity factor – > 90 percent

Dimensions – 60’ x 14’ cylindrical containment vessel module containing reactor and steam generator

Weight – ~ 300 tons as shipped from fabrication

Transportation – Barge, truck or train

Manufacturing – Can be forged and fabricated at any mid-size facility

Cost – Numerous advantages due to simplicity, modular design, volume manufacturing and shorter construction times

Fuel – Standard LWR fuel in 17 x 17 configuration, each assembly 6 feet in length; 24-month refueling cycle with fuel enriched less than 4.95 percent

3. The SVBR (Svintsovo-vismutovyi bystryi reaktor) is one of three liquid-metal-cooled reators currently under development in Russia, along with the sodium-cooled BN-series and the lead-cooled BREST. Unlike the lead- and sodium-cooled reactors, which Rosatom ultimately envisions as very large (1600+ MWe in the case of the case of the BN-series), the SVBR is designed as a small, modular, and passively-safe reactor. SVBR should have 90 gwd/ton (90 gigawatt days per ton of uranium. This is close to being twice as efficient with Uranium as existing light water reactors.)

The Oil Drum coverage of the SVBR

On July 9, 2008, the company director of power machine engineering in the Russian Machines Company, Vladimir Petrochenko, announced that his company had made a commitment to invest US$400-500m in a joint venture with the State Corporation Rosatom to build the first SVBR-100 commercial power reactor in Obninsk which is in the Kaluga Region [Nuclear.Ru2008]. At that time the project was expected to take approximately seven years with a tentative completion date of 2015.

Subsequently, at the 2nd International Conference “Construction of Nuclear Power Plants” which was held in Moscow in November 2008, Anna Kudryavtsev said that the total investments in the SVBR-100 project are currently estimated at 16bln Rubles. Updated estimates of the time line for the reactor’s construction indicated that the design project should be ready by 2017 with a pilot reactor being installed by 2020. She noted that the SVBR-100 is likely to become the world’s first commercial reactor cooled by liquid heavy metal

Small nuclear reactors reviewed.

The SVBR is an integral design, with the steam generators sitting in the same Pb-Bi pool at 400-480ºC as the reactor core. It is designed to be able to use a wide variety of fuels, though the reference model uses uranium enriched to 16%. Uranium-plutonium fuel is also envisaged. The unit would be factory-made and shipped as a 4.5m diameter, 7.5m high module, then installed in a tank of water which gives passive heat removal and shielding. A power station with 16 such modules is expected to supply electricity at lower cost than any other new Russian technology as well as achieving inherent safety and high proliferation resistance. (Russia built 7 Alfa-class submarines, each powered by a compact 155 MWt Pb-Bi cooled reactor, essentially an SVBR, and 70 reactor-years operational experience was acquired with these.)

4. Hyperion Power Generation Uranium Hydride Reactor

Hyperion Power generation is trying to make a factory mass produced uranium hydride molten core reactor which will generate 70 MWt and 27-30MWe. Hyperion Power Generation plans to sell and build the first 4000 reactors over the first ten year period or less. [2013-2022] They have orders from Romania and Czechs and are now talking to developers in the Cayman Islands, Panama and the Bahamas. 4,000 reactors over ten years is an average of 400 per year or 10-12 GW per year.

5. Chinese Will Build Modular High Temperature Nuclear Reactors Like Cans of Soda: in Eight Packs China will make dozens of these reactors for use in China.

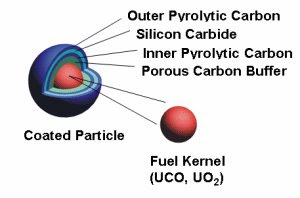

China is developing the high temperature gas-cooled reactor-pebble-bed module (HTR-PM). It adopts a two-zone core, in which graphite balls are loaded in the central zone and the outer part is fuel ball zone, and couple with a steam cycle. Outer diameter of the reactor core is 4.0 m and height of the core is 9.43 m. The helium inlet and outlet temperature are 250 and 750 C, respectively. An earlier design of the reactor had thermal power of 380 MW. Preliminary studies show that the HTR-PM is feasible technologically and economically. In order to increase the reactor thermal power of the HTR-PM, some efforts have been made. These include increasing the height of reactor core, optimizing the thickness of fuel zone and better selection of the scheme of central graphite zone, etc. The reactors will probably initially have about 100 gwd/ton and later designs should improve to 200-600 gwd/ton. [Gigawatt days per ton]. Maximum burnup 100% of actinides would mean about 1000 gwd/ton.

Reactor Power: 400 MWt

Electrical Output: 165 MWe

Outlet Conditions: Up to 900°C (1652°F)

Coolant: Helium

Fuel Design: ~450,000 low-enriched UO2 TRISO fuel particles in pebbles

Refueling: Online

Letter of Intent: Updated March 24, 2009

Licensing Plan: Design Certification

Expected Submittal: FY2013

6. Westinghouse International Reactor Innovative and Secure (IRIS) 335 MWe

Reactor Power: 1000 MWt

Electrical Output: 335 MWe

Outlet Conditions: 330°C

Coolant: Light water

Fuel Design: 17 x 17 assemblies 4.95% enrichment UO2

Refueling: 3-3.5 years

Letter of Intent: Updated March 18, 2009

Licensing Plan: Design Certification

Expected Submittal: Q3 2012

Design Information: Pressurized water reactor with reactor vessel, helical-coil steam generators, reactor coolant pumps, and pressurizer within a reactor vessel which is enclosed in a spherical steel containment vessel.

7. Toshiba Super-Safe, Small and Simple (4S) 10 MWe reactor

Coolant: Liquid-metal (sodium)

Fuel Design: 18 hexagonal fuel assemblies – U-10%Zr Alloy with 19.9% enrichment

Licensing Plan: Design Approval

Expected Submittal: October 2010

Design Information: Small, sodium-cooled, underground reactor

8. Liquid Fluoride Thorium Reactor has been proposed but is not funded.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.