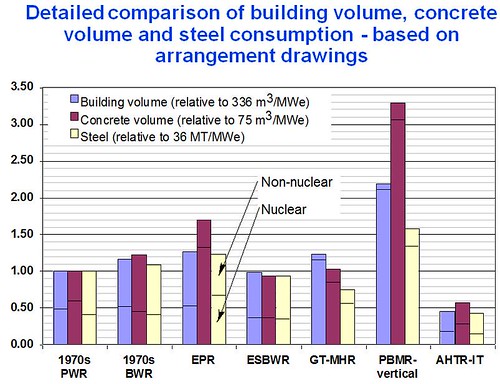

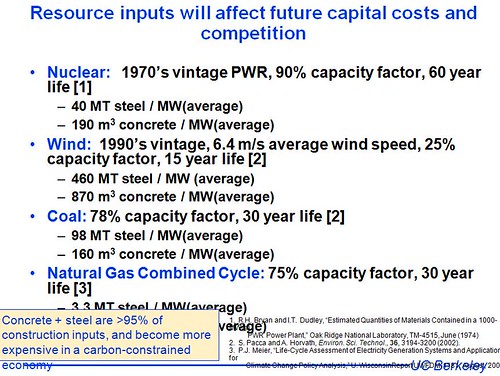

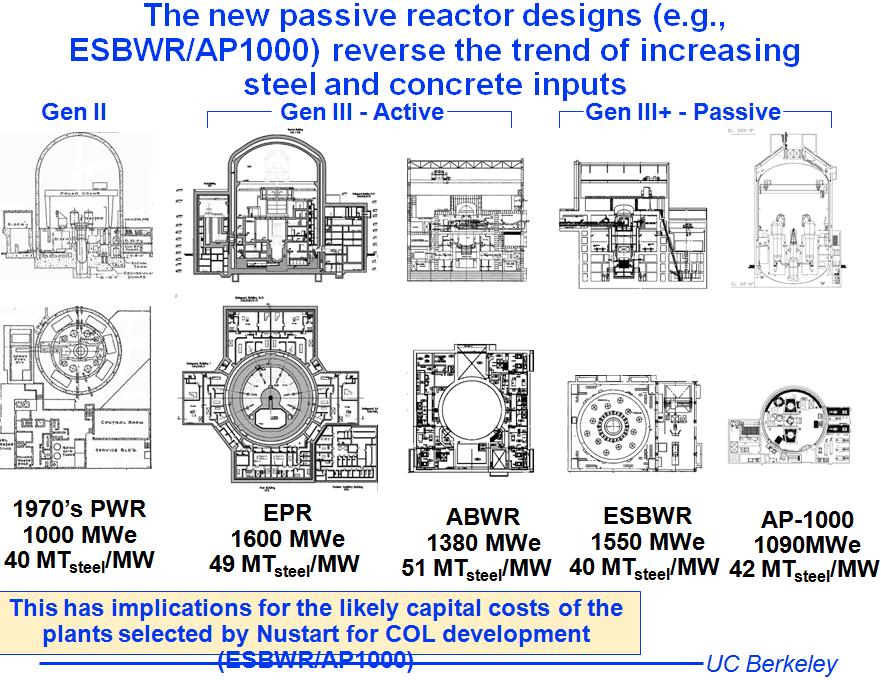

Per Peterson, Prof at Berkeley provides information on construction material for energy. 95% of construction inputs are steel and concrete.

China is making 1250MW AP1000’s now, 1400MW in the next batch and 1700MW for the ones after that

Information is mostly from this Per Peterson powerpoint presentation on nuclear energy

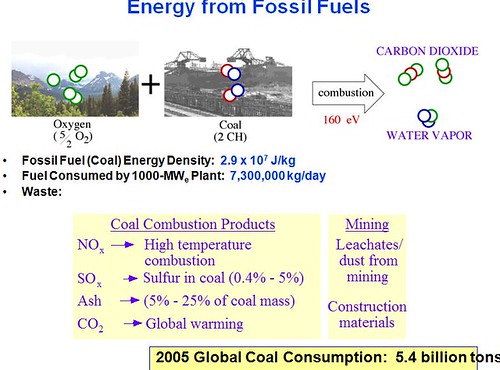

Energy from coal, 7.3 million kg per day for a 1GW plant.

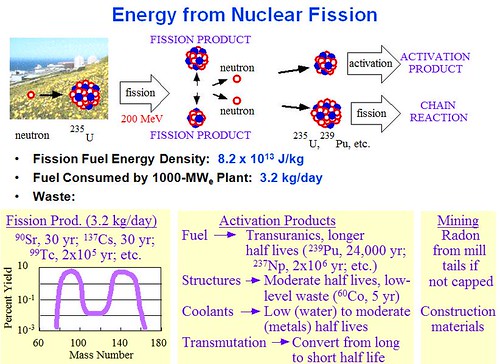

Energy from nuclear fission, 3.2kg of fuel used per day for a 1GW plant.

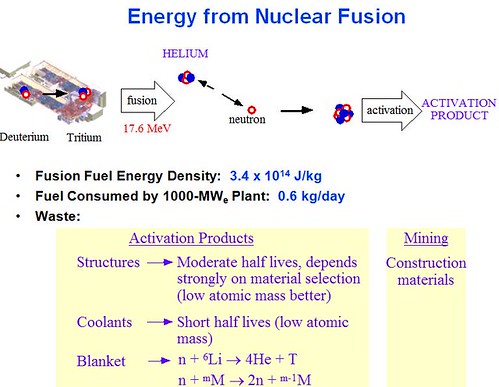

Energy from nuclear fusion. 0.6kg per day of fuel for a 1GW plant

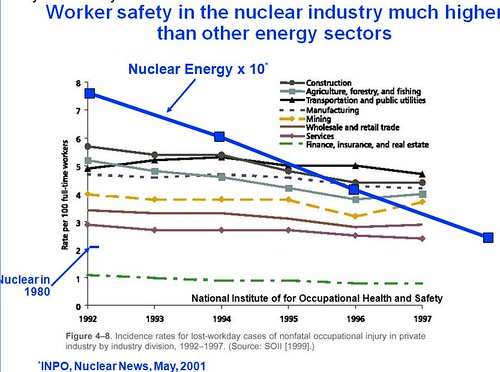

Nuclear safety study from 2004

Nuclear workers compared to other industries

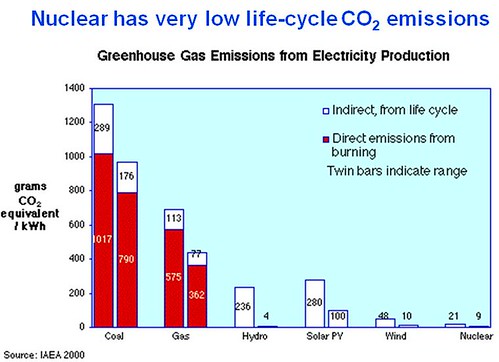

CO2 comparison for different energy sources

FURTHER READING

Nuclear Energy: 1996, 2006, 2016 by Per Peterson

Nuclear Research by Per Peterson

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.