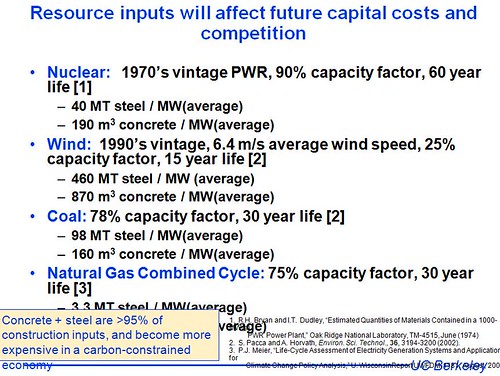

Per Peterson, Prof at Berkeley provides information on construction material for energy. 95% of construction inputs are steel and concrete. This article looks at the most recent wind turbines and finds that wind power’s need for a lot of steel and concrete is not substantially changed from the 1990 figures. 700-1000 tons (not including all support structures beyond tower and base) per MW (nuclear equivalent power adjusted for capacity factor) for offshore wind for 5MW turbines. 840-1250 tons (after 20-25% support structure adjustments) puts the amount of material needed at the level of the 1990 wind machines. There is another article on this site that updates the concrete and steel inputs for nuclear reactors Some High Temperature nuclear reactor designs would cut the amount of material usage by a lot. Wind material usage can be cut using Kitegen designs, “whale bumps” on the blades for more efficiency and other design improvements.

Concrete monopole foundation for wind turbines

Enercon 4.5MW offshore turbine weighs 440 tons (looks like mostly steel) Does not look like it includes any support structures or the tower.

The REpower 5M turbine features a rotor diameter of 126 metres and a Top Head Mass (THM; nacelle + rotor) of 430 tonnes [not including tower, foundation and support structures.]

It would require investments in the range of around €3.6 billion throughout Germany [assuming on budget], which translates in terms of job creation volume into 25,000 and 40,000 ‘man years’. [So US$5B and about 30,000 man years or 60 million man hours, for 1.5GW -reduce by capacity factor for projects running 2007-2011]

Mathis argued that future 5-7 MW offshore wind turbines erected in 25-40 metre deep water will require new foundation solutions. If such huge foundations were constructed as steel monopiles, the required diameter would be in the range of 8-10 metres and the total length about 50-60 metres. Utilization of jacket type or tripod type foundations with similar capacity and water depth range will, in his view, result into even higher demands with regard to fabrication, welding complexity and corrosion protection. This points to concrete foundations as the solution. However, the construction of gravity-based concrete foundations requires sophisticated formwork systems and new transport logistics methods to deal with component masses between 3000 and 7000 metric tonnes.

Three substructures were considered for the final selection process:

centre column tripod (CCT);

flat faced tripod (FFT);

OWEC jacket quatropod (OJQ), a four-legged jacket solution.According to the study a CCT design requires cast nodes to improve fatigue performance, bringing the total mass up to 1080. The FFT needs three large 96-inch (243 cm) diameter piles but no cast components, while the substructure mass is 1140 tonnes. Finally the OJQ is based on a design from OWEC Tower A/S, a ‘traditional’ jacket structure adapted for REpower 5M wind turbine use.

The mass of the lightweight structure, including three 72-inch piles for fixing the substructure to the seabed, is approximately 600 tonnes.(For more general information on the Beatrice project see Renewable Energy World November-December 2006)

So 600-1140 tons plus 450 tons for the nacelle and rotors for a 5MW wind turbine (1.5 MW of equivalent nuclear power). 700-1000 tons per MW (nuclear equivalent power adjusted for capacity factor) for offshore. Land based could be less but there are size limitations on land and tower must be built higher to get same wind quality

.

Enercon 6MW model has 36 concrete section

Previously, in-situ concrete (125 m hub height) or steel towers (97 m hub height) were used for the E-112/6 MW. The towers for the E-126/6 MW will be 131 meters tall and made up of 36 concrete segments manufactured at WEC Turmbau Emden GmbH. Once completed, the hub height will reach 135 metres and the overall height an impressive 198 metres.

a diagram of the major component assemblies (8000 parts) and the 2007 eight page article discusses wind power supply chain issues.

20-25% of offshore wind is the support structures

Better wind mapping shows at 100 meter elevations 40-45% capacity factors can be found for some sites.

Integrated wind can deal with many issues that have been laid out as problems.

FURTHER READING

2006: Thirty seven Nordex N62 wind turbines (6340 tons) NORDEX N 62 69 m hub height 1.3 MW rated power. So 6340 for 50 MW of nameplate power or 16MW equivalent of nuclear power. 400tons per MW (nuclear equivalent)

Calculations could be produced using wind turbine design principles

This 2001 8 pager has a table with percentage of materials for different components of wind turbines

Though wind turbines don’t consume fuel, it takes at least 150,000 lb of steel, concrete, and fiberglass to build a single 3-MW turbine. Thus, turbines have a carbon footprint that is laid down before they ever generate a single kilowatt. And detractors point out that steel and concrete are both energy intensive, carbon-emitting industries. There are also networks of roads needed to service wind farms. And wind turbines take land, somewhere between 60 and 300 acres/MW. (For comparison, nuclear and coal plants generate about 1,000 MW/acre).

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

Comments are closed.