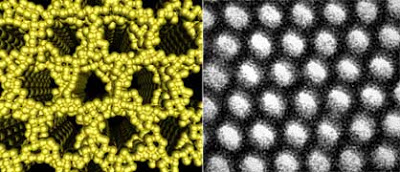

Self assembly of the nanostructure of platinum has been performed on a bulk scale. They used the new method to create a platinum structure with uniform hexagonal pores on the order of 10 nm across (a nanometer is the width of three silicon atoms). Platinum is, so far, the best available catalyst for fuel cells, and a porous structure allows fuel to flow through and react over a larger surface area. The researchers have made fairly large chunks of porous platinum this way, up to at least a half-centimeter across. In addition to making porous materials, the researchers said, the technique could be used to create finely structured surfaces, the key to the new field of plasmonics, in which waves of electrons move across the surface of a conductor with the information-carrying capacity of fiber optics, but in spaces small enough to fit on a chip.

Cornell researchers have developed a method to self-assemble metals into complex nanostructures. Applications include making more efficient and cheaper catalysts for fuel cells and industrial processes and creating microstructured surfaces to make new types of conductors that would carry more information across microchips than conventional wires do.

“This is exciting,” Wiesner said. “It opens a completely novel playground because no one has been able tostructure metals in bulk ways. In principle, if you can do it with one metal you can do it with mixtures of metals.

The Weiser group has been studying mesostructured silicates.

The method involves coating metal nanoparticles — about 2 nanometers (nm) in diameter — with an organic material known as a ligand that allows the particles to be dissolved in a liquid, then mixed with a block co-polymer (a material made up of two different chemicals whose molecules link together to solidify in a predictable pattern). When the polymer and ligand are removed, the metal particles fuse into a solid metal structure.

“The polymer community has tried to do this for 20 years,” said Ulrich Wiesner, Cornell professor of materials science and engineering, who, with colleagues, reports on the new method in the June 27 issue of the journal Science. “But metals have a tendency to cluster into uncontrolled structures. The new thing we have added is the ligand, which creates high solubility in an organic solvent and allows the particles to flow even at high density.”

Another key factor, he added, is to make the layer of ligand surrounding each particle relatively thin, so that the volume of metal in the final structure is large enough to hold its shape when the organic materials are removed.

The Weiser group is doing a lot of interesting science.

An earlier step in their research

Cornell researchers have developed a “one-pot” process to create porous films of crystalline metal oxides that could lead to more efficient fuel cells and solar cells

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.