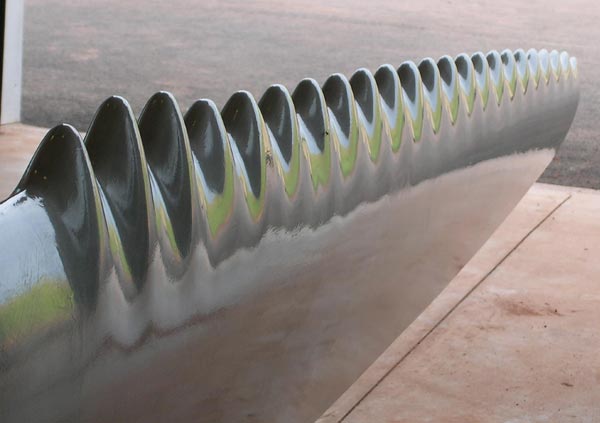

WhalePower, based in Toronto, Ontario, is testing this wind-turbine blade at a wind-testing facility in Prince Edward Island. The bumps, or “tubercles,” on the blade’s leading edge reduce noise, increase its stability, and enable it to capture more energy from the wind.

Credit: WhalePower

I have talked frequently about nuclear power uprating (changes in fuel design and other changes that can increase the power generated at existing nuclear power plants. Now there is reports that bumpy wind turbine blades could uprate existing and future wind turbines. The new wind turbine blades come from WhalePower of Toronto, Ontario, Canada. Uprates can be very good, because you spend a lot less to get a lot more out of what is already there.

Prototypes of wind-turbine blades have shown that the delayed stall doubles the performance of the turbines at wind speeds of about 17 miles per hour and allows the turbine to capture more energy out of lower-speed winds. For example, the turbines generate the same amount of power at 10 miles per hour that conventional turbines generate at 17 miles per hour. The tubercles effectively channel the air flow across the blades and create swirling vortices that enhance lift.

WhalePower can rapidly develop precise designs for retrofit leading edges or fully integerated tubercle technology blades for any turbine.

-Retrofit blades are stronger than the original unmodified blades.

-Integrated blades meet or exceed all required performance crieria.

They should be commercially available later this year (2008).

Stephen Dewar, director of research and development at WhalePower, says that ongoing tests at the Wind Energy Institute of Canada, in the province of Prince Edward Island, have shown the tubercle-lined blades to be more stable, quiet, and durable than conventional blades. “The turbine has survived being hit by the edge of a hurricane, and it survived wind-driven snow and ice,” he says.

WhalePower has also shown in demonstrations that tubercle-lined blades on industrial ceiling fans can operate 20 percent more efficiently than conventional blades can, and they do a better job at circulating air flow in a building.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

Comments are closed.