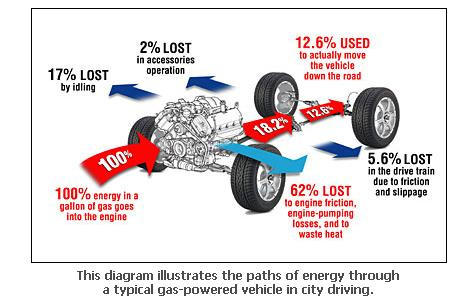

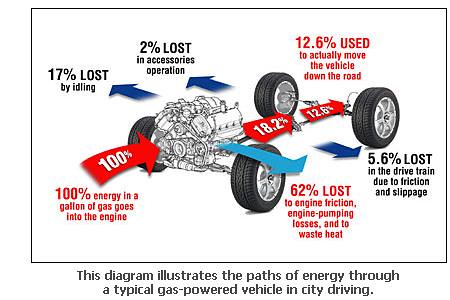

More than 60 percent of the energy that goes into an automotive combustion cycle is lost, primarily to waste heat through the exhaust or radiator system.

2007 information on the projects to get thermoelectrics into commercialization

The Department of Energy’s Office of Freedom CAR and Vehicle Technologies initiated a program 13 years ago with Hi-Z Technologies to develop a 1 kW thermoelectric generator to either replace or augment the alternator in Heavy Duty Trucks. This unit was operated for the equivalent of 500,000 miles on the PACCAR test track. It demonstrated the feasibility of the concept which helped justify the competitive procurement to develop a commercially viable vehicular thermoelectric generator that would improve fuel economy by 10+ percent. Three teams were selected, 2 for Spark Ignition Gasoline engine powered autos and 1 for diesel engine powered heavy duty trucks. BSST teamed with Visteon, BMW and Marlow is scheduled to introduce their Thermoelectric Generator integrated into BMW’s Model Year 2011 Series 5 cars producing 750 watts. BSST’s parent company, Amerigon, has supplied over 4 million thermoelectric Climate Control Seats to GM, Ford, Toyota, Nissan, Hyundai and several other OEM’s. They are the largest supplier of thermoelectric devices in the world. The General Motor’s (GM’s) Team includes General Electric (GE), NASA’s Jet Propulsion Lab and the Oak Ridge National Lab. GM is planning to introduce a production car at the 2010 Detroit Auto Show with a 350 watt thermoelectric generator. Michigan State University is heading up a team with the Cummins Engine Company, NASA’s Jet Propulsion Lab, and Tellurix to develop a thermoelectric generator heavy duty truck to operate on diesel engine exhaust.

Work is under way developing a vehicular thermoelectric air conditioning/heater system.

Nextreme is a company that makes confetti size thermoelectric devices

Physical size comparison of eTEC centered on standard thermoelectric cooler

A company called Powerchips believe that they can achieve 70-80% carnot efficiency. This compares very favorably with a Rankine cycle generator, such as a gas turbine, has a typical Carnot efficiency of about 30%, while a diesel or gasoline generator is only about 10-15% efficient in Carnot terms.

Since cars currently waste up to a third of the energy in gasoline as exhaust heat, using Power Chips to recover a significant fraction of that power could provide ample electricity for new systems, and could act as a replacement for existing alternators.

FURTHER READING:

All of the presentations on capturing waste heat at the recent DEER conference on diesel engine efficiency

TG daily has some coverage of thermoelectrics for cars and trucks

The exhaust on diesel truck stacks can reach temperatures above 600F. This common, easily accessible and available portal provide a significant differential potential which could be tapped and then reclaimed as electrical energy. Such energy would be fed back into the truck in some manner (via a large electrical-assist motor?), thereby increasing fuel efficiency. Dr. Tritt believes such technology could save an estimated 1.5 billion dollars annually at only 7% to 8% efficiency.

This waste heat could be converted to electricity in many industrial processes by using new, high-temperature, quantum-well-thermoelectric materials. The technology also should be directly applicable to the recovery of energy losses in the petroleum refining, chemicals, forest products, iron and steel, food and beverage, cement, fabricated metals, transportation, textiles, mining, plastics, aluminum, and glass industries.

16 page agenda of the 13th annual diesel engine efficiency and emissions research conference (DEER)

All of the conference presentations

Oak Ridge National Laboratory research in 2007 for greater efficiency in cars and trucks includes thermoelectric. The near term goal is to capture 10% of the waste heat from a truck.

They are also worknig on overall engine efficiency:

In 2006, 150-horsepower diesel engines for passenger cars had a 41.5% thermal efficiency whereas 400-horsepower diesel engines for trucks had a 45% thermal efficiency. The DOE thermal efficiency goals are 45% by 2010 for diesel cars and 55% by 2012 for trucks. With widespread implementation of new improvements, we could realize a fuel reduction of 20%.

Directory of thermoelectric generators from PESwiki

Nanowerk reviewed thermoelectrics using custom nanostructured material

Cars that are more fuel efficient than a Toyota prius now and ones that will be available soon

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.