We are getting closer to cyborgs that are as strong and as fast as people.

“That means it has about 10 times as much power as other arms despite the fact that the design hasn’t been optimized yet for strength or power,” Goldfarb says.

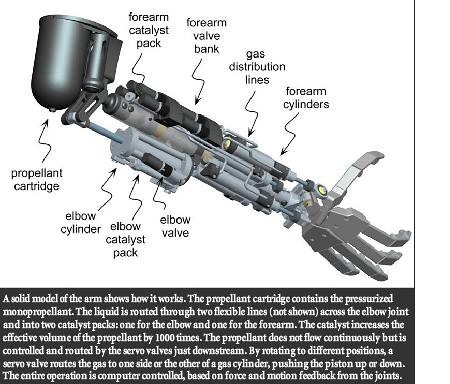

Rocket arm

The mechanical arm also functions more naturally than previous models. Conventional prosthetic arms have only two joints, the elbow and the claw. By comparison, the prototype’s wrist twists and bends, and its fingers and thumb open and close independently.

The Vanderbilt arm is the most unconventional of three prosthetic arms under development by a Defense Advanced Research Project Agency (DARPA) program. The other two are being designed by researchers at the Advanced Physics Laboratory at Johns Hopkins University in Baltimore, who head the program. Those arms are powered by batteries and electric motors. The program is also supporting teams of neuroscientists at the University of Utah, California Institute of Technology and the Rehabilitation Institute of Chicago who are developing advanced methods for controlling the arms by connecting them to nerves in the users’ bodies or brains.

Goldfarb’s power source is about the size of a pencil and contains a special catalyst that causes hydrogen peroxide to burn. When this compound burns, it produces pure steam. The steam is used to open and close a series of valves. The valves are connected to the spring-loaded joints of the prosthesis by belts made of a special monofilament used in appliance handles and aircraft parts. A small sealed canister of hydrogen peroxide that easily fits in the upper arm can provide enough energy to power the device for 18 hours of normal activity.

One of their immediate concerns was protecting the wearer and others in close proximity from the heat generated by the device. They covered the hottest part, the catalyst pack, with a millimeter-thick coating of a special insulating plastic that reduced the surface temperature enough so it was safe to touch.

To allow for thermal expansion, the engineers replaced the arm’s nine valves with a set machined to a slightly lower tolerance, approximately 100 millionths of an inch. “We were astonished at by the difference between 50-millionths and 100-millionths: It made all the difference in the world,” says Goldfarb.

Their biggest problem operating with hot gas turned out to be finding belt material that was strong enough and could withstand the high temperatures involved.

They found a material that works: the engineering thermoplastic polyether ether ketone

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

Comments are closed.